Fuel Tank Cap Precision Customize CNC Machining Motorcycle Automotive Auto Aluminum Casting Parts

Basic Info.

| Model NO. | RQ-DCA-P032 |

| Machining | Grinding |

| Material | Aluminum Alloy |

| Surface Preparation | Spray Coating |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 4 |

| Casting Surface Quality Level | 1 |

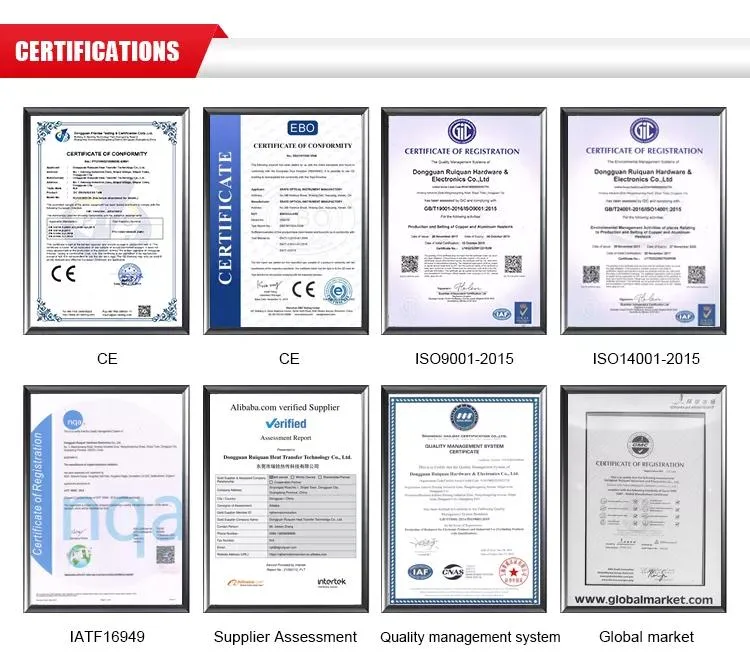

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008, IATF16949 |

| Aftersale Service | The Best |

| MOQ | Small MOQ |

| Processing | Die Casting, CNC Machining, Drilling, etc |

| Materials | Aluminum Alloy ADC12, Zinc Alloy, etc |

| Mold | Designing and Free Dfm |

| Production Line | 10 |

| Inspection | Full Inspection Before Shipping |

| Delievery | Fast Delivery |

| Drawing Format | Pdf, Dxf, Dwg, Step, Igs, X-T, etc. |

| Custom | Non-Brands |

| Surface Treatment | Paint, Powder Spraying, Electroplating, etc |

| Certificates | So9001:2015 IATF16949, Rosh |

| Product Name | Aluminum Heat Sink |

| Size | Customized Size |

| Warranty | 2years |

| Transport Package | Customer Requirements |

| Specification | Customer Requirements |

| Trademark | OEM |

| Origin | Made in China |

| HS Code | 7616999000 |

| Production Capacity | 500000PCS/Month |

Product Description

| Type of Business | Factory/Manufacturer(ODM&OEM) |

| Product Name | Fuel tank cap Precision Customize CNC Machining Motorcycle Automotive Auto Aluminum Casting Parts |

| Materials | Aluminium ( A6063, 7075, ADC12 ,A360,A380 etc );Zinc ( zamak 3,zamak 5 etc ) |

| Processing Method | (Click for more) Die casting / Aluminum extrusion / Cold forging and CNC Machining are available) |

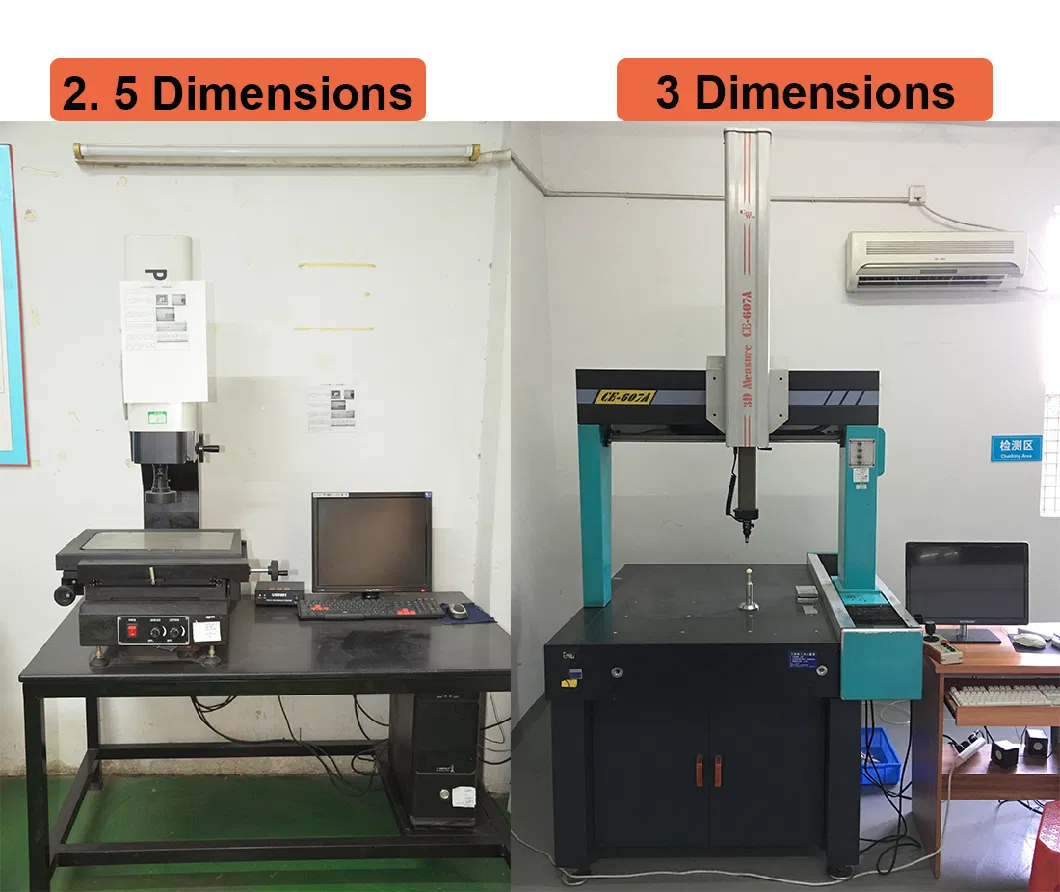

| Testing Equipment | Airtightness Tester, Salt Spray Tester, X-ray Flaw Detector, Quadratic Test, Cubic Test, Roughness Tester, Film Thickness Tester,Constant Temperature and Humidity Chamber, Vibration Tester, RoHs Tester, Hardness Tester,Two/Three-dimensional Detector |

| Tolerance | +/-0.05mm~ +/-0.2mm |

| Surface Treatment | Paint, Powder spraying, Electroplating, Electrophoresis, Anodic oxidation, Passivation, Sand blasting, Screen printing(Manufactured to customer requirements) |

| Drawing Format | PDF, DXF, DWG, STEP, IGS, x-t, etc. |

Other related products

Mass products of Die-casting heat sinks and housing

CustomizationAluminum metal spare parts,like heatsink,housing,enclosure,etc.Please share your technical drawings(2D&3D).Let's make them real.Professional Equipment

DONGGUAN RUIQUAN GROUP CO.,LTD

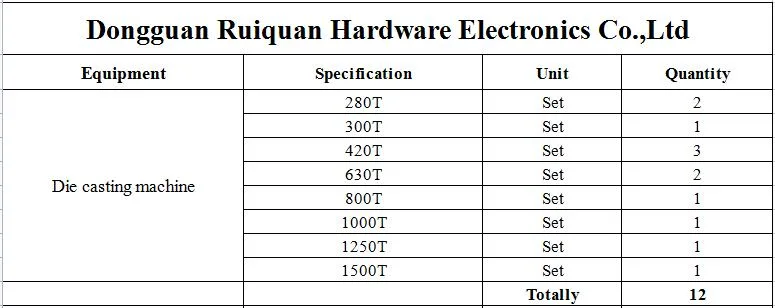

Workshop area:Totally 20000 square meters. Experienced employees:350 peopleMain equipment:12sets Die casting machines from 280-1500T

10 auto-grinding machines,10 manual grinding lines

50pcs CNC precessing centers these can meet customers' various requirements.

Post Processing--Manual grinding and Auto-machine grinding

Our Advantages| QUALITY is our culture. | |

| RICH EXPERIENCE | 20 years experience of One-stop Design and Manufacturing Solutions from mold Designing (Free DFM)-making to mass production. |

| COST CONTROL | Optimize cost maximizely from the aspects of materials buying,production,processing and transportation,etc. |

| QUALITY CONTROL | Following ISO9001 and IATF16949 Standards/Full inspected before package. |

| STRONG EXECUTIVE POWER | Quotation in 24 HOURS/Quick response/Fast delivery. |

Dongguan Ruiquan Hardware Electronics Co., Ltd is a ODM&OEM manufacturer of aluminum /copper /zinc products specializing in providing high-quality heat conduction, mainly producing aluminum extrusion/die casting heatsink/cold forging heatsinks and parts, heat dissipation modules and various CNC processing products.

Since it's established in 2003, the company has adhered to the service tenet of "Meeting customers' needs, continuing innovation, reducing heat energy, reducing thermal resistance, improving product quality, and extending product life", and has been recognized by customers in IT, NEV, Communications, LED lamps, Industrial electronics and other industries.Our Soul: Environmental protection, energy saving, heat dissipation.Our Mission: Serve the society.Program: Optimization and Innovation1. Optimize low-end products&take the route of MID-to-high-end products.2. Continuously develop new products, reform and innovate.Appeal: To meet customer needs and achieve common development.

We are able to make molds by ourselves according to customers' requirements.

1. Who are we?We are based in Guangdong, China, start from 2010,sell to Western Europe(40.00%),Domestic Market(40.00%),North America(8.00%),South America(5.00%),Southeast Asia(5.00%),Eastern Asia(2.00%). There are total about 101-200 people in our office.2. How can we guarantee quality?Always a pre-production sample before mass production;Always final Inspection before shipment;3.What can you buy from us?Cold Forging Heat Sink,Aluminum Extrusion Heat Sink,Aluminum Extrusion Housing4. Why should you buy from us not from other suppliers?Dongguan Ruiquan Hardware Electronics Co.,LTD,covering more than 20,000 square meters.,We are dedicated to the development of electronics and led light heat sinks. With ten years of experience in R&D.Owning 200 pcs production equiment(CNC ,cold forging ect)5. What services can we provide?Accepted Delivery Terms: FOB,CIF,EXW,FCA,DDP,DDU,Express Delivery;Accepted Payment Currency:USD,EUR,HKD,CNY;Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash,Escrow;Language Spoken:English,Chinese

Short lead time:

| Products Name | Order(in the last 12month) | Shortest Lead Time |

|---|---|---|

| Cold Forging Heat Sink | 500 Pieces | 20 Days |

| Aluminum Extrusion Heat Sink | 300 Pieces | 15 Days |

| Aluminum Extrusion Housing | 500 Pieces | 15 Days |