Pneumatic Parallel Sliding /Double Disc/ Ceramic Gate Valve (GAZ644TC) / Ball Valve / Check Valve / Inlet Valve / Discharge Valve/Feed Valve/Wear

Overview Pneumatic Parallel Sliding /Double Disc/ Ceramic Gate Valve (GAZ644TC) / Ball Valve / Check Valve / Inlet Valve

Overview

2.Check carefully whether marks and the nameplate on the valve meet operating requirements.

3. This valve can be insstalled on pipelines at any angle.

4. This valve shall be fully open or fully closed in running and not be used as a throttle valve, or else its sealing surfaces will be washed and get worn faster.

5. For Long term storage, it shall be stored in a dry and ventilated room whth periodic check to avoid rust.

6. Knocking shall be avoided in the transportation process.Product Features

2. The double gates adopt floating connection to produce reliable one-way seal under the medium pressure action. Also the floating connection can drive the gate to rotate up in opening/closing due to misaliginment of axial lines so that the friction grains between the valves' gate and seat are distributed evenly to produce no linear abrasion, thus improving its service life greatly.

3. Sealing surfaces of the valve's body and gate are lined with anti-wear ceramics, with excellent resistance to abrasion.

4. Being compact, it's easy for transportation, installation and maintenance.

Working Principle

Product Parameters

View of the factory

Basic Info.

| Actuator | Manual, Pneumatic, Electric |

| Seal Surface | Parallel Gate Valve |

| Thread Position of Valve Rod | Outside Gate Valve |

| Usage | Emptying |

| Standard | DIN |

| Application | Industrial Usage |

| Medium | Dry Ash in Power Plant, Slurry, Cement Ash, Powder |

| Design Pressure | Pn10, Pn16 |

| Size | DN50-DN400 |

| Suitable Temperature | Below 150 Deg C |

| Transport Package | Plywood Case |

| Specification | CE, SGS, GMP |

| Trademark | GOOLE, OEM |

| Origin | Wenzhou, Zhejiang, China |

| HS Code | 8481804090 |

| Production Capacity | 50, 000 PCS/Year |

Product Description

Pneumatic Parallel Sliding /Double Disc/ Ceramic Gate Valve (GAZ644TC) / Ball Valve / Check Valve / Inlet Valve / Discharge Valve/Feed Valve/Wear-ResistanceProduct Description

Application

1. Design and Manufacture: GB/T 12224

2. Face to Face Dimension: Manufacturer's Standard

3. Flange Dimension: JB/T 79.1, ANSI B16.5 DIN 2543, JIS B2020

4. Inspection and Test: GB/T 9092

5. Material Standard: GB/T 12229 for Carbon Steel, GB/T 12230 for Stainless Steel

Installation, Use & Maintenance:

1. Before Installation, it's necessary to clean the valve and remove possible defects caused in the transportation process.2.Check carefully whether marks and the nameplate on the valve meet operating requirements.

3. This valve can be insstalled on pipelines at any angle.

4. This valve shall be fully open or fully closed in running and not be used as a throttle valve, or else its sealing surfaces will be washed and get worn faster.

5. For Long term storage, it shall be stored in a dry and ventilated room whth periodic check to avoid rust.

6. Knocking shall be avoided in the transportation process.Product Features

Structural Features:

1. Use a Cylinder as the actuator to drive the gate directly to move up and down, with fast opening/closing.2. The double gates adopt floating connection to produce reliable one-way seal under the medium pressure action. Also the floating connection can drive the gate to rotate up in opening/closing due to misaliginment of axial lines so that the friction grains between the valves' gate and seat are distributed evenly to produce no linear abrasion, thus improving its service life greatly.

3. Sealing surfaces of the valve's body and gate are lined with anti-wear ceramics, with excellent resistance to abrasion.

4. Being compact, it's easy for transportation, installation and maintenance.

Working Principle

Working Principle

When the cylinder drives the gate to move downwards through the valve's stem, sealing surfaces of the valve's gate and body will be engaged to cut off the channel, namely, closing; the other way around is opening.Product DetailsMain Parts and Materials

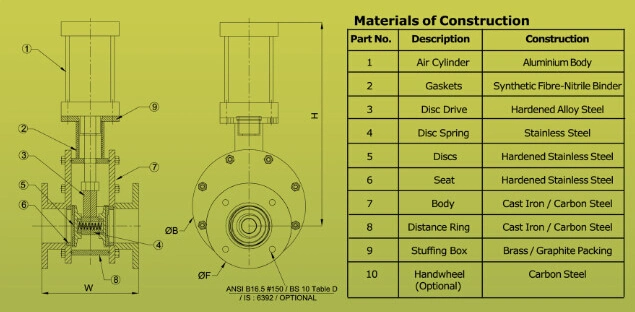

| Sr No. | Parts | Material | Sr No. | Parts | Material |

| 1 | Body | WCB | 7 | Middle Body | WCB |

| 2 | Disc | Ceramic | 8 | Packing | Flexible Graphite |

| 3 | Seat | Ceramic | 9 | Packing Gland | 2Cr13 |

| 4 | Stem | 2Cr13 | 10 | Bracket | Q235 |

| 5 | Stud | 35CrMoVA | 11 | Pneumatic Actuator | Aluminum Body |

| 6 | Nut | 25 |

Main External and connecting Dimensions

| DN | PN | L | D | D1 | C | H | n-d | |

| 50 | 10 | 200 | 160 | 125 | 16 | 520 | 4-18 | |

| 65 | 220 | 180 | 145 | 18 | 595 | 4-18 | ||

| 80 | 240 | 195 | 160 | 20 | 635 | 8-18 | ||

| 100 | 280 | 215 | 180 | 20 | 630 | 8-18 | ||

| 125 | 300 | 245 | 210 | 22 | 715 | 8-18 | ||

| 150 | 320 | 280 | 240 | 24 | 840 | 8-23 | ||

| 175 | 320 | 310 | 270 | 26 | 885 | 8-23 | ||

| 200 | 350 | 335 | 295 | 26 | 1155 | 8-23 | ||

| 250 | 400 | 405 | 350 | 30 | 1400 | 8-23 | ||

| 300 | 450 | 460 | 400 | 30 | 1800 | 12-23 |

Send to us